-360°C high temperature resistance

-Long life cycles over 10,000 times

-10^5~10^9 surface resistivity

-Low thermal conductivity

-Excellent resistance against soldering fluxes

location:Home > Products > Solder Pallet Series > ESD CDM 68910

-360°C high temperature resistance

-Long life cycles over 10,000 times

-10^5~10^9 surface resistivity

-Low thermal conductivity

-Excellent resistance against soldering fluxes

| ESD CDM Sheet | |||

| Size (MM) | Weight(KG/PC) | Size (MM) | Weight(KG/PC) |

| 3 x 1020 x 1220 | 7.09 | 10 x 1020 x 1220 | 23.64 |

| 4 x 1020 x 1220 | 9.46 | 12 x 1020 x 1220 | 28.37 |

| 5 x 1020 x 1220 | 11.82 | 15 x 1020 x 1220 | 35.47 |

| 6 x 1020 x 1220 | 14.19 | 20 x 1020 x 1220 | 47.29 |

| 8 x 1020 x 1220 | 18.91 | 25 x 1020 x 1220 | 59.11 |

| ESD CDM Sheet | |||

| Size (MM) | Weight(KG/PC) | Size (MM) | Weight(KG/PC) |

| 3 x 1220 x 2440 | 16.96 | 10 x 1220 x 2440 | 56.56 |

| 4 x 1220 x 2440 | 22.62 | 12 x 1220 x 2440 | 67.87 |

| 5 x 1220 x 2440 | 28.28 | 15 x 1220 x 2440 | 84.84 |

| 6 x 1220 x 2440 | 33.94 | 20 x 1220 x 2440 | 113.12 |

| 8 x 1220 x 2440 | 45.25 | 25 x 1220 x 2440 |

141.40 |

Note: stock available for 3-15mm thickness material

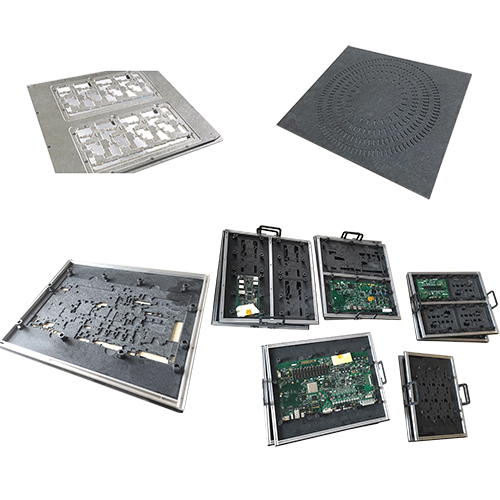

CDM is a composite material made of glass fiber mat and high mechanical strength resin. With good performance against electric arc and tracking, it is an ideal material for solder paste printing,SMT process,reflow soldering and wave soldering.Due to high hardness and strength of fiber glass, we recommend carbide or diamond toolings for machining this material. Regular replacement of the toolings is necessary.

CDM's function in PCB assembly

1.Avoid pollution due to human contact

2.Reduce disposal rate

3.Prevent PCB from bending

4.Standardize the width of production line

5.Impove production capacity by using multi-functional fixtures

6.Cover the SMT parts at bottom, make the partial welding available

Tips for machining CDM material

1. The material of the cutter: carbide such as Tungsten Carbide +Cobalt

2. How many flutes for the cutter ? 4 flutes

3. Feed speed(cutting speed): for 3.175mm cutter, feed speed is 2000mm/min

4. Wall thickness:1mm