-360°C high temperature resistance

-Long life cycles over 10,000 times

-10^5~10^9 surface resistivity

-Low thermal conductivity

-Excellent resistance against soldering fluxes

location:Home > Products > Solder Pallet Series > Solder Pallet Material

-360°C high temperature resistance

-Long life cycles over 10,000 times

-10^5~10^9 surface resistivity

-Low thermal conductivity

-Excellent resistance against soldering fluxes

| Weight Table of 1020x1220mm | |||

| Size (MM) | Weight(KG/PC) | Size (MM) | Weight(KG/PC) |

| 3 x 1020 x 1220 | 7.09 | 10 x 1020 x 1220 | 23.64 |

| 4 x 1020 x 1220 | 9.46 | 12 x 1020 x 1220 | 28.37 |

| 5 x 1020 x 1220 | 11.82 | 15 x 1020 x 1220 | 35.47 |

| 6 x 1020 x 1220 | 14.19 | 20 x 1020 x 1220 | 47.29 |

| 8 x 1020 x 1220 | 18.91 | 25 x 1020 x 1220 | 59.11 |

| Weight Table of 1220x2440mm | |||

| Size (MM) | Weight(KG/PC) | Size (MM) | Weight(KG/PC) |

| 3 x 1220 x 2440 | 16.96 | 10 x 1220 x 2440 | 56.56 |

| 4 x 1220 x 2440 | 22.62 | 12 x 1220 x 2440 | 67.87 |

| 5 x 1220 x 2440 | 28.28 | 15 x 1220 x 2440 | 84.84 |

| 6 x 1220 x 2440 | 33.94 | 20 x 1220 x 2440 | 113.12 |

| 8 x 1220 x 2440 | 45.25 | 25 x 1220 x 2440 |

141.40 |

Note: stock available for 3-20mm thickness material

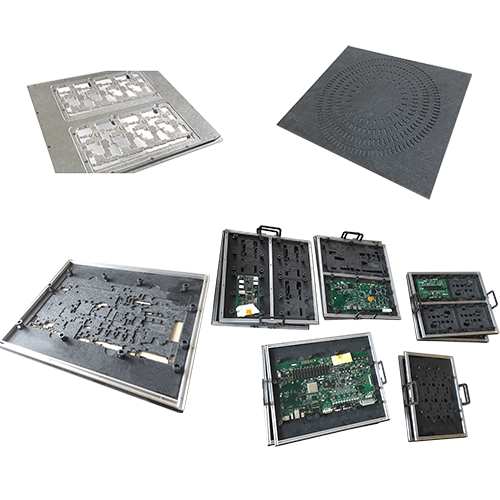

It is a black composite material made of glass fiber mat and high mechanical strength resin. With good performance against electric arc and tracking, it is an ideal material for solder paste printing,SMT process,reflow soldering and wave soldering.Due to high hardness and strength of fiber glass, we recommend carbide or diamond toolings for machining this material. Regular replacement of the toolings is necessary.

Function in PCB assembly

1.Avoid pollution due to human contact

2.Reduce disposal rate

3.Prevent PCB from bending

4.Standardize the width of production line

5.Impove production capacity by using multi-functional fixtures

6.Cover the SMT parts at bottom, make the partial welding available

Tips for machining solder pallet material

1. The material of the cutter: carbide such as Tungsten Carbide +Cobalt

2. How many flutes for the cutter ? 4 flutes

3. Feed speed(cutting speed): for 3.175mm cutter, feed speed is 2000mm/min

4. Wall thickness:1mm

5 ways to maximize the life of solder pallet

What are the most important things to pay attention to while using solder pallet ?

1. Gentle care and proper handling. Fracture damage most often occurs while transferring the unit. To avoid damage to the protective wall, as well as other parts of the solder pallet fixture, it is important to have a dedicated management position.

2. Store the solder pallet fixtures in an upright position. Deformations can be happened if the unit is improperly stored. To avoid deformations caused by stacking it is recommended that units be stored on shelves.

3. Avoid strong acid and alkali contact. Exposure to strong acids or bases will easily corrode the solder pallet fixture. To avoid this a neutral flush is recommended.

4. Avoid using alcohol and alcohol-based cleaning agents. Saponifiers are the recommended cleaning agent.

5. Shockproof transportation. Units can receive shock damage while being transported through the A shockproof cart is recommended.

-SMT carrier

-Wave solder pallet

-Reflow solder pallet

-Solder paste screen printing in SMT

-PCB online testing jig

-Component protection

-Component insertion

-Pressfit fixtures